Copyright © Shindary Automotive Parts Co., Ltd. All Rights Reserved

The fuel system is fascinating, to say the least. It is a system that contains many parts that all work in sync to continuously deliver fuel to the engine.

I've always wanted to learn more about the fuel system and how it works. So, I did some research online and talked to a few mechanics and this is what I learned.

Before working on any part of your vehicle, you must follow these three simple rules.

1. No smoking. Never smoke while working on the fuel system and keep the workbench away from open flames and sparks.

2. Safety first. Always wear safety glasses when working on or around any vehicle.

3. Relieve fuel system pressure. You will need to relieve fuel system pressure before connecting a pressure gauge. There are 5 ways to relieve fuel system pressure.

Most vehicles use two fuel systems. They are very similar, but they deliver fuel in a slightly different way.

1. Fuel system return type

The return type fuel system components are

1. a fuel tank

2. A fuel pump

3. Fuel line

4. A fuel filter

5. Fuel rail with injector

6. Pressure regulator

7. Return line

On a return fuel system, the pressure regulator is located on the fuel rail. There was a time when gravity moved fuel from the vehicle's fuel tank to the carburetor. Today's programmed fuel injection systems require a pressurized and constant supply of fuel to the injectors at all times. This constant pressurized fuel supply is achieved by a fuel pump.

2. Reflux-free fuel system

The non-return type fuel system has the following components.

1. A fuel tank

2. A fuel pump

3. A fuel filter

4. Pressure regulator

5. Fuel line

6. Fuel rail with injector

On non-return fuel systems, the pressure regulator is located in the fuel tank.

1.Fuel Pump

The fuel pump has the ability to pressurize the fuel system to start the engine and then continue to supply fuel to the injectors while the engine is running. When you turn on the ignition, the ECM PCM activates the pump relay for 2 seconds to turn on the pump and pressurize the system.

If the ECM PCM does not register the engine as running, it will close the relay, thus stopping the fuel pump. If the ECM PCM does see the engine running, it will keep the fuel pump running. Some vehicles are equipped with multi-speed fuel pumps. These fuel pumps allow for more precise control of the fuel supply. In older models, the ECM PCM varies the pump speed by applying low or high pressure to the pump depending on the engine fuel requirements.

When less fuel is required, the ECM PCM deactivates the fuel pump relay and current is passed through the fuel pump resistor to reduce the pump output. When fuel demand increases, the ECM PCM activates the fuel pump relay, allowing current to bypass the resistor and flow directly to the pump to increase output.

New models are equipped with a separate fuel pump control unit (FPCU) that has the ability to change the fuel pump speed based on driving conditions. The fuel pump has three operating speeds: low, medium and high. When the engine speed and load are low, the fuel pump receives 9 volts. Then, as engine speed and load increase, the voltage increases to 10 volts.

Pump components include

1. Filter pump

2. Electric pump

3. Impeller relief valve

4. One-way check valve

The pump is submerged in fuel and electrically driven by the impeller, which draws fuel through the filter and creates pressure. The fuel is then discharged through a one-way check valve. The purpose of the check valve is to prevent the pressure in the fuel rail from flowing back into the fuel tank when the fuel pump is shut off. This way, the fuel system will have sufficient pressure when the vehicle is started. If the pressure is too high, the pressure relief valve will open and vent the fuel back into the tank.

The purpose of the regulator is to keep the fuel at a constant and specific pressure. There is a slight difference between a return type regulator and a non-return type regulator. The regulator consists of a housing valve, a diaphragm and a spring. The spring keeps the valve closed and allows fuel pressure to build up on the diaphragm.

When the fuel pressure exceeds the spring pressure, the valve opens, allowing excess fuel to drain and return to the fuel tank. The regulator on a return fuel system is located near the end of the fuel rail. When the regulator is connected to the intake manifold, vacuum is directed to the pressure regulator to help overcome the spring force. This is done to maintain a constant pressure. difference between fuel pressure and manifold air pressure.

When the throttle is closed, the manifold vacuum is high and the manifold pressure is low. This results in a lower fuel pressure. As the throttle opens, manifold vacuum decreases and manifold pressure increases. This results in higher fuel pressure.

The regulator connected to the intake line is not controlled by engine vacuum. The hose is there to provide unrestricted movement of the regulator diaphragm. These types of regulators work like non-return regulators, where the ECM PCM compensates for changes in intake manifold pressure.

In the non-return type system, the regulator is located in the fuel tank and is part of the fuel tank unit. To maintain the fuel cooler and reduce evaporative emissions, the manufacturer does not place a return line between the fuel rail and the fuel tank.

3. Fuel Pressure Dampers

Some vehicles are equipped with fuel pulsation dampers on the fuel rail. Fuel pressure dampers are used to absorb pressure pulses and reduce the noise caused by rapid opening and closing of injectors. The damper consists of a diaphragm and a calibrated spring. The injector opens and closes and generates a pressure shock wave, which is absorbed by the diaphragm as it compresses the spring.

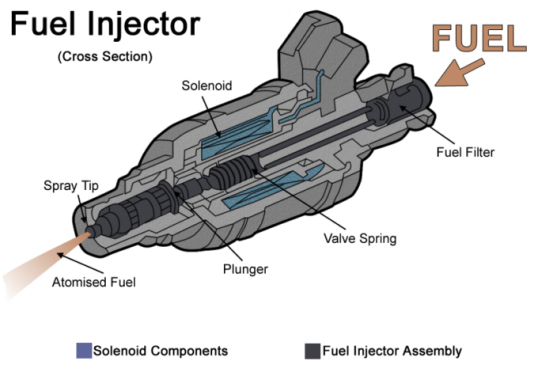

4. Fuel Injector

The injector injects atomized fuel into the intake of the cylinder. This action is electric. They are normally closed. the ECM/PCM fully opens the injectors at precise times, measured in milliseconds, to deliver the correct amount of fuel to mix with the incoming air. The longer the injectors are in the open position, the more fuel is injected into the combustion chamber. The fuel injector body is sealed between the intake manifold and the fuel rail.

The internal components of the injector include.

1. inlet screen

2. Electrical connector

3. Solenoid coil

4. a plunger

5. A discharge nozzle

Injector discharge nozzles are designed to optimize fuel atomization by producing extremely fine droplets. Improved atomization provides enhanced engine performance and reduced emissions.

Fuel must have a constant fuel pressure so that the ECM PCM can accurately control the air-fuel ratio. Low fuel pressure can be caused by low or no pump output, restricted filter, restricted filter, restricted supply line, or a stuck open or weak spring in the regulator.

To isolate the component causing the low pressure, you can always check any applicable service bulletins or service news articles and follow the procedures they provide. If no bulletin or service news article is available, start with the easiest component to test.

1. Check the fuel line

First check the fuel line between the fuel tank and fuel rail for leaks, broken pipes and other damage.

2. Check the pressure regulator

On a return fuel system, the pressure regulator will be the next starting position. To determine if the pressure regulator is stuck open due to excessive pressure, clamp the return line with a swivel jaw hose clamp. If the pressure is elevated, the regulator is likely to be faulty.

3. Replace the fuel filter and coarse filter suction filter

If the pressure regulator is working properly, the fuel filter and coarse filter suction filter should be replaced. Before replacing them, you need to make sure that there is no longer any condition that caused them to clog. Otherwise, they may quickly become clogged again. If you are using a non-return fuel system, replace the pressure regulator and fuel filter.

4. Check fuel pressure

If your vehicle has been cranking for a long time or is difficult to start, observe the pressure reading immediately after shutting down the engine. Rapid fuel pressure drops should not occur immediately after shutdown. If the pressure drops quickly, internal possibilities are: check valves in the fuel pump not seated, leaking injectors, pressure regulator not closed, or external leaks such as fuel hoses and lines.

5. Test Injectors

Remove the fuel rail and injectors together and check for leaks by turning the ignition on and off. You can also check the injectors for leaks by clamping the fuel inlet and return lines and monitoring the fuel pressure.

6. Check the fuel pump check valve

If the injectors are normal, then the fuel pump check valve is the problem and the pump needs to be replaced. Please note that the check valve is an integral part of the fuel pump and cannot be replaced separately.

7. Look for restrictions in the return line after the regulator

High fuel pressure may be due to a faulty regulator or an obstructed return line after the regulator. First check the vacuum hose connected to the regulator. If it is disconnected or blocked from the manifold vacuum, the pressure will be high. If you see fuel in the vacuum line, the pressure regulator diaphragm is leaking and needs to be replaced.

Like other electrical components on your vehicle, fuel pumps and injectors require electricity to operate. However, they don't just run all the time. Instead, they are controlled by the ECM PCM through a relay to run at the correct time.

A relay is an electromagnetic switch that has two sides: power and control. the ECM PCM operates the control side of the relay, which provides the power path to the injectors and fuel pump. The fuel injector is the on/off solenoid that injects fuel into the intake of the cylinder. The fuel injectors require power and ground to operate.

Power to the injectors comes from the PGM-FI main relay, which is energized whenever the ignition switch is turned on.The ECM PCM provides the ground path to the injectors. This is also how it turns the injectors on and off. When there is no ground, the injectors are off and do not inject fuel. When grounded, the injectors turn on and inject fuel. The longer the grounding time, the longer the injectors are open and the more fuel goes into the combustion chamber.

The ECM PCM uses various inputs to calculate exactly when the grounded injector open time should start and how long it should last. The open time is called the "injector duration" and is measured in milliseconds - thousandths of a second.

When the vehicle is slowed down with the throttle closed, the ECM PCM closes the injectors to save fuel and reopens the injectors before the engine reaches idle speed. This function is called "fuel cut-off" and is a normal function. Fuel cutoff also occurs when the engine speed is too high, regardless of throttle position. This is done to protect the engine from over-revving.

The heart of a vehicle's fuel injection system is an electric pump located in the fuel tank. The pump delivers a constant volume of fuel at high pressure to the engine in order to provide an adequate supply to the injectors at all times. Depending on the vehicle, the fuel pump can be serviced separately or as part of a modular fuel sender assembly. Please note that modular assembly is more expensive because it combines multiple components into one unit.

The fuel pump filter is your vehicle's first line of defense against fuel system contamination. It is often referred to as the fuel sock because of its appearance. The filter is located in the fuel tank, just below the pump. In addition to filtering out contaminants, the filter also provides wicking action, drawing fuel into the pump much like liquid is drawn into an absorbent paper towel. While the filter is not a maintenance item, it should always be replaced if you are installing a new fuel pump.

The electric pumps used in fuel injection systems are capable of delivering fuel at pressures that exceed the requirements of the engine. Therefore, use a regulator to adjust the fuel delivery pressure according to the engine load. A faulty regulator can cause incorrect fuel pressure, which can lead to various engine performance problems such as stalling, hesitation and lack of power.

The regulator is mounted on the fuel rail as it may not be easily accessible on this engine. As a result, replacement costs will vary. The efficiency of today's engines is due in large part to fuel injectors controlled by on-board computers. Injectors inject fuel into the cylinders in precise amounts.

Most of today's engines are equipped with multi-point fuel injection, using one injector per cylinder. Injectors are mounted on rails located on the intake manifold. Faulty injectors can cause a variety of symptoms, from difficult starts to hesitation. Note that on some engines, the injectors may be difficult to access, which will significantly increase the cost of replacement.

As the name implies, the oxygen sensor detects the amount of oxygen present in the exhaust gas and then transmits that information to the on-board computer. The oxygen sensor allows the computer to make continuous adjustments to the air-fuel mixture to achieve maximum engine performance with minimal emissions.

The oxygen sensor is also used to evaluate the efficiency of the catalytic converter based on its ability to store and release oxygen. Unlike other engine sensors, the oxygen sensor is a maintenance item. They require periodic inspection and replacement at the manufacturer's recommended intervals.

Previous: SPARE PARTS NUMBERS FOR BYD S6

Shindary Automotive Parts Co., Ltd.